Industry 4.0 is the project of the German Government to encourage traditional industries such as manufacturing towards computerization and equip them with high technology. The purpose in this new industry is to characterize the integration of compliance, resource efficiency and ergonomics in both customers and business partners.

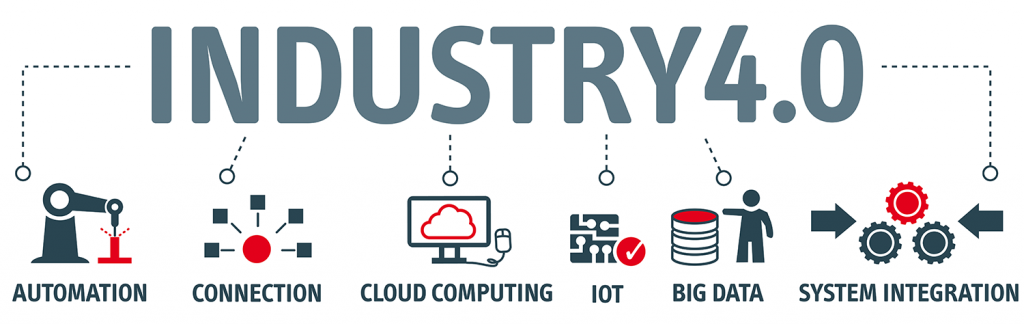

It is a concept that every living and non-living object will be connected to the internet and become communicating, the communication between machines brings smart production, and its economic and social transformations, which we are currently discussing. Industry 4.0 is known by many as the 4th Industrial Revolution.

It is an industry term that includes contemporary and modern automation systems, data exchange, and production technologies. This industrial revolution includes the internet of things, internet services and physical-virtual systems. It saves time and helps to increase productivity by reporting every data obtained by hosting it with technology.

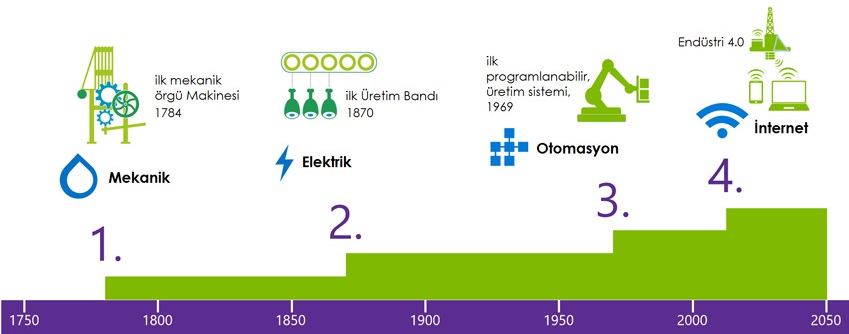

The first industrial revolution, Industry 1.0, started with the development of mechanical production systems using water and steam power. The second industrial revolution, Industry 2.0, enabled mass production with the possibilities of electrical power. The Third Industrial Revolution, Industry 3.0, is also called the digital revolution. With the use of electronics and the development of science and technology, production has become more automated. In the 18th century (in 1712) the first industrial revolution began with the invention of the steam engine. With the invention of the telegraph and telephone in the 19th century, mass production based on electricity and the division of labor began. With the invention of the first microcomputer in 1971, the story of automation of production processes began.

What Will The Effects of Industry 4.0 Be?

► Machine control will increase by moving from labor force to technology control systems.

► The manpower needed will be reduced due to automatic systems.

► Its impact on socio-economic working life will be felt.

► The industry will gain a different value and reach a large share in the market that provides this integration.

In the days we live in the era of smart systems talking to each other, decision making with data awareness and environmentally friendly production; As BEFAŞ Elektrik, we are taking firm steps towards developing equipment and company-specific technology solutions for all layers of Industry 4.0. We are already imagining how the production will take shape in 15-20 years and we are trying to plan this process. During this period, we are in a constant development as to where opportunities will be experienced and where value will be created.

In the world that provides smart reports to managers at the decision support point of production such as data collection, processing, making predictions with machine and data learning techniques, we aim to provide digitalization according to the needs of our customers by knowing well the requests and processes of our customers.

In line with our goal of reaching environmentally conscious and sustainable production, we intend to produce solutions for different needs on different platforms and offer them to our customers.

Follow Befaş Elektrik’s progress on the way to Industry 4.0 and discover the power of data-based production!